Sports Tech Startup Full Development Support

A European/American sports tech startup focusing on smart sports equipment development. From 5-person team to Series A, 8 months from concept to production with Italy field testing support.

Client Background

A European/American sports tech startup focusing on smart sports equipment development. Initial team of only 5 people, needed to build the first-generation product from scratch.

Partnership Start: Complete Journey from Concept to Production

Initial Challenges (2018)

- Team Size: 5-person startup team with no manufacturing experience

- Product Positioning: Smart sports sensing device, needs to be installed on professional sports equipment

- Technical Challenges: Extreme environment durability, miniaturized structural design, mass production process development

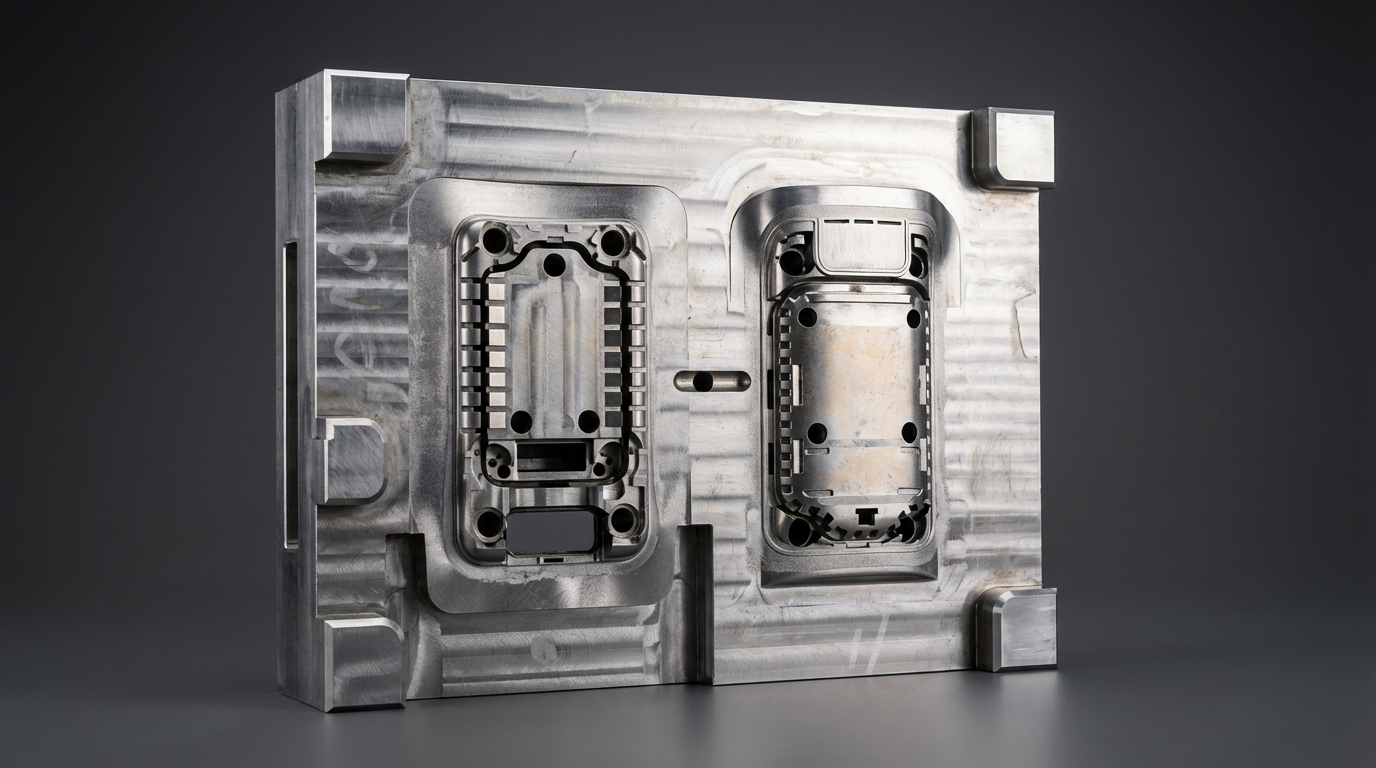

Precision mold: Dual-cavity design for complex housing structure

Mold details: Precision machining ensures product dimensional stability

Copper electrode manufacturing: Multiple electrode sets for EDM mold detailing

Mold flow analysis: On-machine testing to optimize injection parameters

Deep Technical Collaboration

1️⃣ Product Structural Design and Material Selection

Environmental Challenges:

- Usage Environment: Snow environment (-20°C ~ +10°C)

- Installation Position: Bottom of sports equipment, withstanding high-frequency impact

- Protection Requirements: Waterproof (IP67), UV resistant, wear resistant

Material Solutions:

- Housing Material: PC+ABS alloy + glass fiber reinforcement (low temperature resistant, no cracking)

- Sealing Design: Double-layer silicone seal + ultrasonic welding

- Surface Treatment: Wear-resistant coating (passed 10,000 abrasion tests)

2️⃣ Pressure Sensor Integration Design

Technical Challenges:

- Sensor Protection: Must withstand body weight pressure (100kg+) without damage

- Signal Stability: Snow vibration interference, temperature effect compensation

- Manufacturing Yield: Precision requirements for micro component assembly

Innovative Solutions:

- Structural Design: Suspended sensor bracket, dispersing impact force

- Material Selection: TPU cushioning layer + PC protective shell dual protection

- Process Optimization: Automated dispensing + visual inspection, yield rate increased to 98%

3️⃣ Field Testing Support

Italy Snow Field Testing (Winter 2021):

- Engineer Dispatch: Accompanied team to Italian ski resort

- Test Items: Extreme low temperature performance (-15°C actual test), high-speed impact durability (60km/h descent), waterproof performance (8-hour snow water immersion), signal stability (4-hour continuous skiing record)

- On-site Optimization: Adjusted structural design in real-time based on test results

- Fast Iteration: Completed revised samples and retesting within 3 days

Test Results:

- ✅ Successfully passed all extreme environment tests

- ✅ Customer satisfaction: 100%

- ✅ Product launch schedule: Achieved on time

Complete Support from Prototyping to Mass Production

First Batch Production Results

Long-term Partnership (4+ Years)

Ongoing Support

- Second-generation product development: Thinner (20% thickness reduction), longer battery life

- Capacity expansion: From 1,000 pieces/month to 10,000 pieces/month

- Cost optimization: 15% cost reduction through process improvement

- Technology upgrade: Introduced Bluetooth 5.0, wireless charging, and other new features

Partnership Results

- Partnership Duration: 4+ years

- Total Shipments: 50,000+ pieces

- Product Iterations: 3 generations of continuous collaboration

- Client Growth: From 5-person startup to Series A funding

Partnership Highlights

1. Deep Technical Involvement, True Product Development Partner

Full participation from material selection, structural design to field testing. Not just answering 'can we do it', but proactively suggesting 'how to do it better'. Italy field testing support demonstrates our commitment to deep involvement in client product development.

2. Startup-friendly Flexible Cooperation

Support small-batch production (MOQ 1,000 pieces), fast iteration (design changes within 2 weeks), flexible payment terms (installment payments, deferred collection). Accompanied client from 5-person startup to Series A funding, witnessing client success.

3. Fast Time-to-market, 8 Months from Concept to Production

Industry average 12-18 months, we only need 8 months. Rapid prototyping (3D printing) + fast mold development + Italy field testing + mass production verification, one-stop service accelerates product launch.

Startup Team Need a Manufacturing Partner?

We support small-batch production, fast iteration, field testing, accompanying you from concept to production