Industrial Equipment Global Supply Chain Integration

A leading US law enforcement technology equipment manufacturer with products widely used in global police systems. 30+ years strategic partnership, helped client relocate production from China to Vietnam to address geopolitical risks.

Client Background

A leading US law enforcement technology equipment manufacturer, focusing on speed measurement devices, law enforcement recorders, and other professional tools, with products widely used in global police systems.

Partnership Journey (30+ Years)

Long-term Strategic Partnership (1995-Present)

Partnership Duration: 30+ years of stable supply relationship

Service Scope: Evolved from single component supplier to full-service manufacturing partner

Trust Foundation: Consistent quality, technical support, flexible cooperation

Recent Supply Chain Transformation (2020-2024)

Challenge: US-China trade friction led to increased tariffs, client needed to diversify production bases

Solution: Helped relocate multiple production lines from China to Vietnam factory

Results: Successfully reduced 25% tariff costs while maintaining supply stability

Multi-material integrated manufacturing: Plastic injection, aluminum die-casting, cable assembly one-stop service

Harsh environment testing: UV aging test, extreme temperature test (-40°C ~ +85°C)

Metal and plastic dual-material components: Perfect combination of metal parts and plastic housing

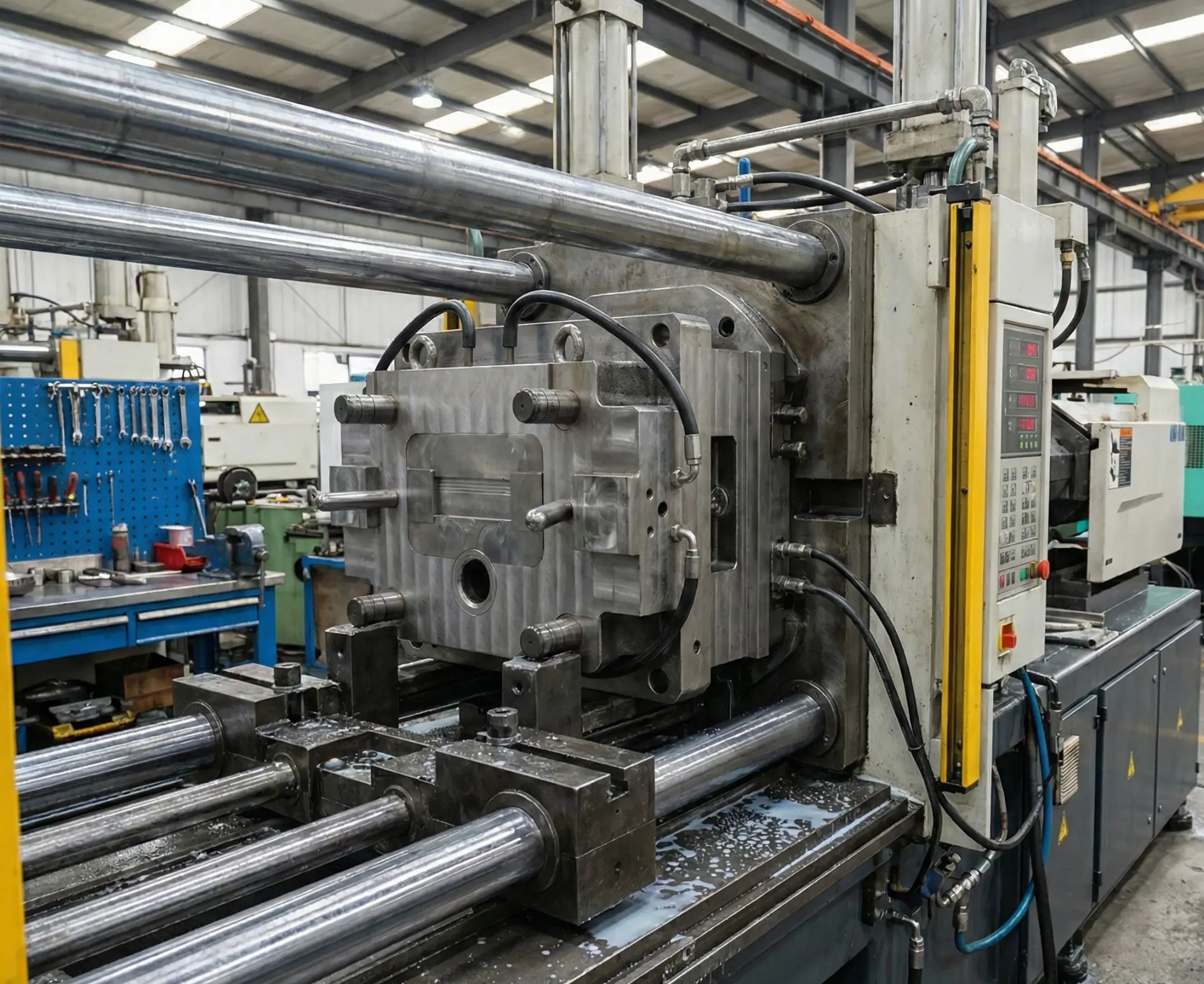

Large injection molding machine: Industrial-grade equipment with stable mass production capability

Service Scope

Plastic Injection Housing

- Material: PC+ABS, glass-filled nylon (PA-GF30)

- Surface Treatment: Anti-UV coating, anti-glare matte finish

Aluminum Die-cast Housing

- Process: High-pressure die-casting + CNC precision machining

- Surface Treatment: Anodizing, powder coating

Cable Assembly

- Customized cable molding, connector assembly

- Meets automotive-grade weather resistance requirements

Technical Challenges and Solutions

Extreme Environment Durability

Challenge:

Products must withstand -40°C ~ +85°C temperature range, intense UV exposure, high-frequency vibration impact

Solution:

- • Use glass-filled nylon (PA-GF30)

- • Add UV stabilizers and antioxidants

- • Pass 1000-hour UV aging test

Low-volume, High-mix Production

Challenge:

20+ models produced simultaneously, monthly demand 500-5,000 pieces per model

Solution:

- • Modular mold design, quick mold change

- • Flexible scheduling system, optimize capacity utilization

- • VMI inventory management, reduce client inventory pressure

Results

Partnership Highlights

1. Multi-material Integration Capability, Simplified Supply Chain

Integrating plastic injection, aluminum die-casting, and cable assembly, clients only need to work with one supplier, significantly reducing management and communication costs.

2. Global Supply Chain Layout, Addressing Geopolitical Risks

Taiwan R&D + Vietnam production, flexibly responding to geopolitical changes. Helped client complete production line relocation within 6 months without affecting delivery schedules.

3. Low-volume, High-mix Flexible Production, Supporting 20+ Models

Modular mold design + flexible scheduling system, producing 20+ models simultaneously, monthly demand 500-5,000 pieces per model, meeting diverse client needs.

Need a Global Supply Chain Integration Partner?

We have 30+ years of industrial-grade manufacturing experience, Taiwan + Vietnam dual bases, helping you address geopolitical risks