Professional plastic injection molding services, complete solutions from concept to product.

Your Design, Solidified.

From concept to product, we transform your ideas into precision plastic components.

Combining advanced technology with customized services to create the perfect solution for your needs.

Our Services

ComprehensiveCustom Services

We provide complete plastic injection molding solutions, from design consultation to mass production, meeting your every need.

Rapid Prototyping

Quickly produce samples to confirm product design and functionality before mass production.

- Fast Delivery

- Precision Manufacturing

- Multiple Iterations

- Quality Assurance

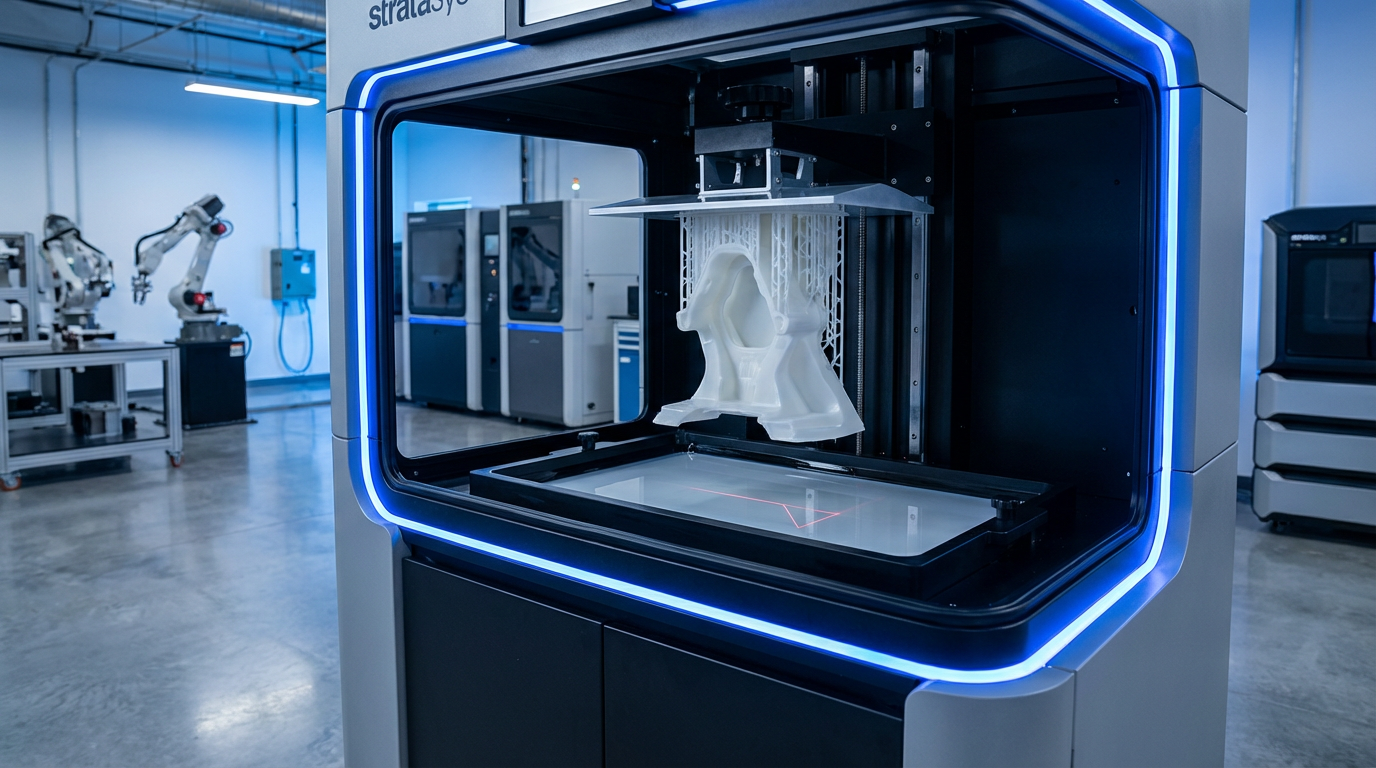

Free 3D Printing

Contracted customers enjoy up to 3 free 3D printing services to ensure perfect verification before molding.

- Pre-mold Verification

- Dimension Confirmation

- Structure Testing

- Rapid Iteration

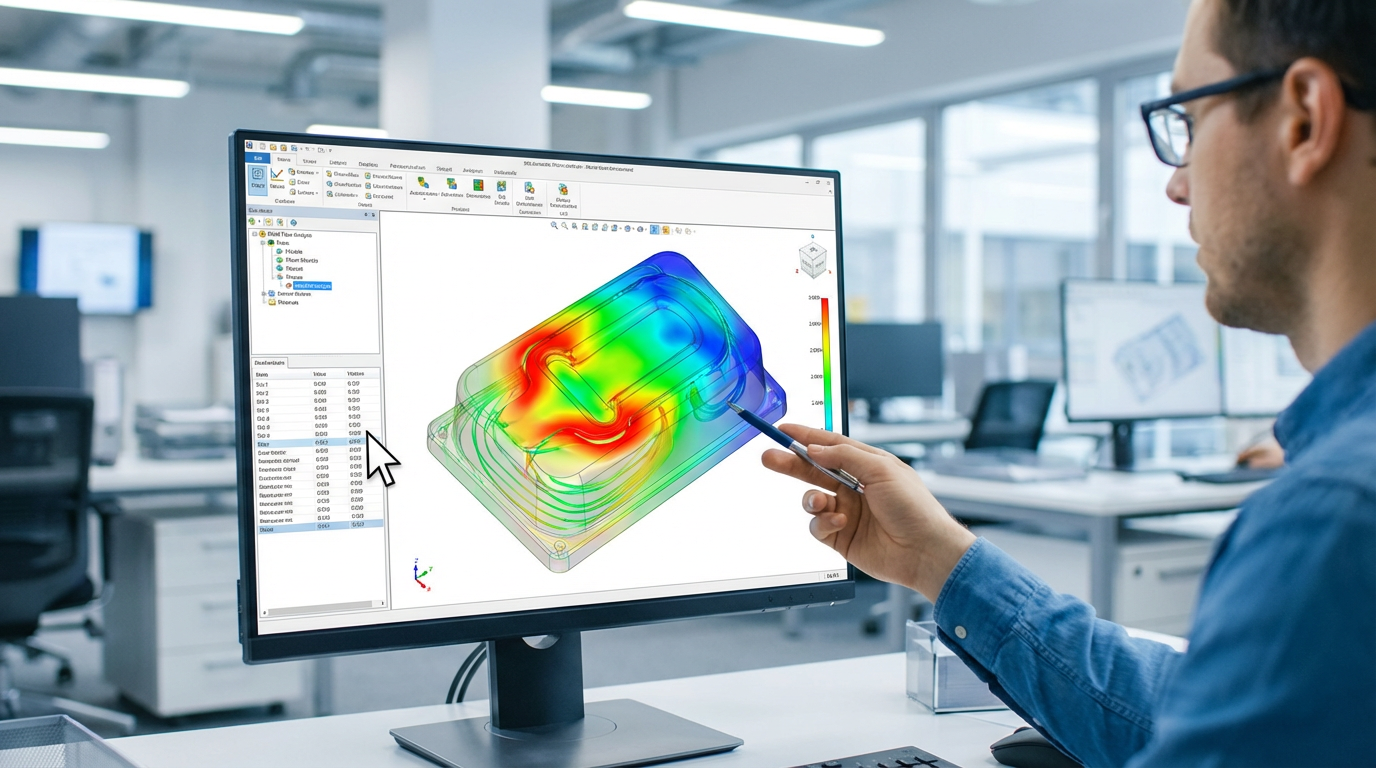

Mold Flow Analysis

Use advanced simulation software to predict injection flow behavior and optimize mold design.

- Flow Simulation

- Fill Time Prediction

- Shrinkage Analysis

- Mold Optimization

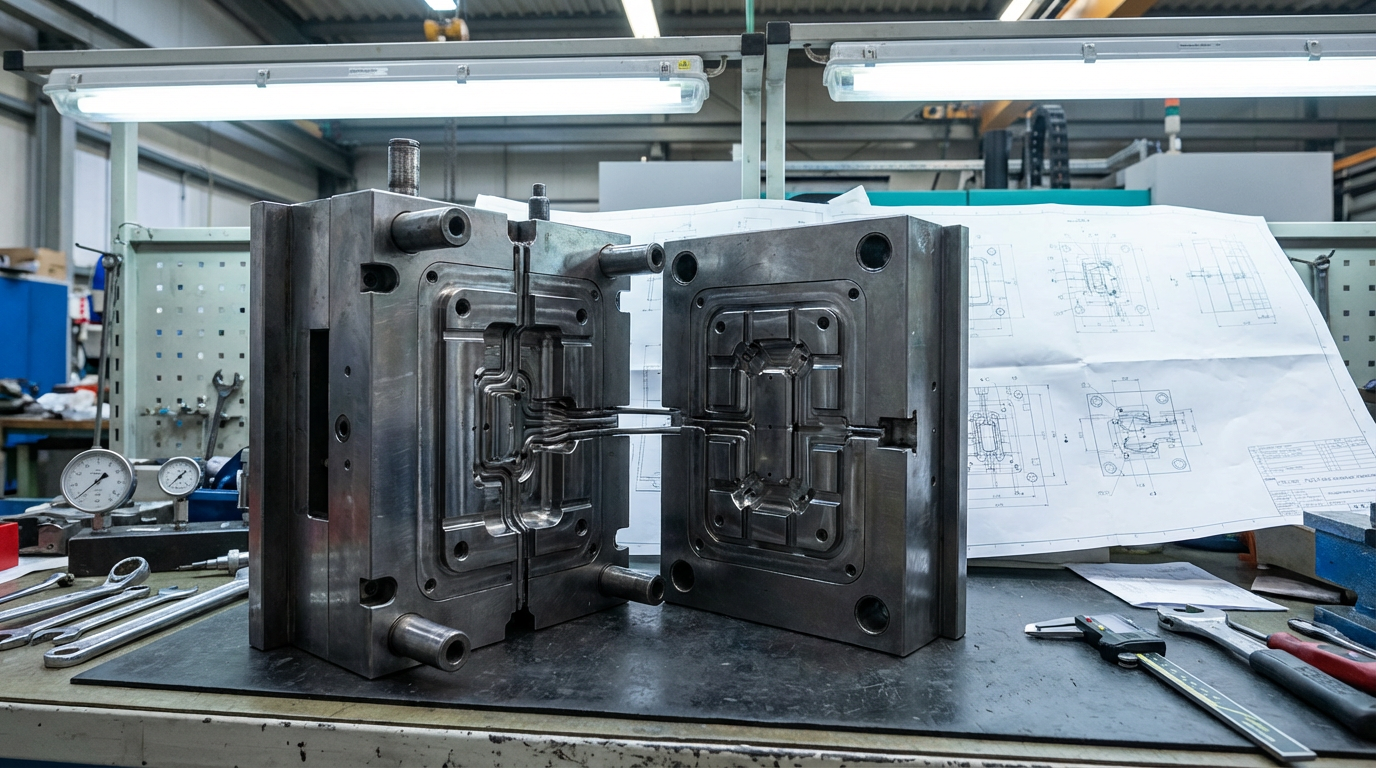

Mold Design

Professional mold design team, from concept to reality, providing complete solutions.

- Mold Flow Analysis

- Structure Optimization

- Precision Machining

- Mold Maintenance

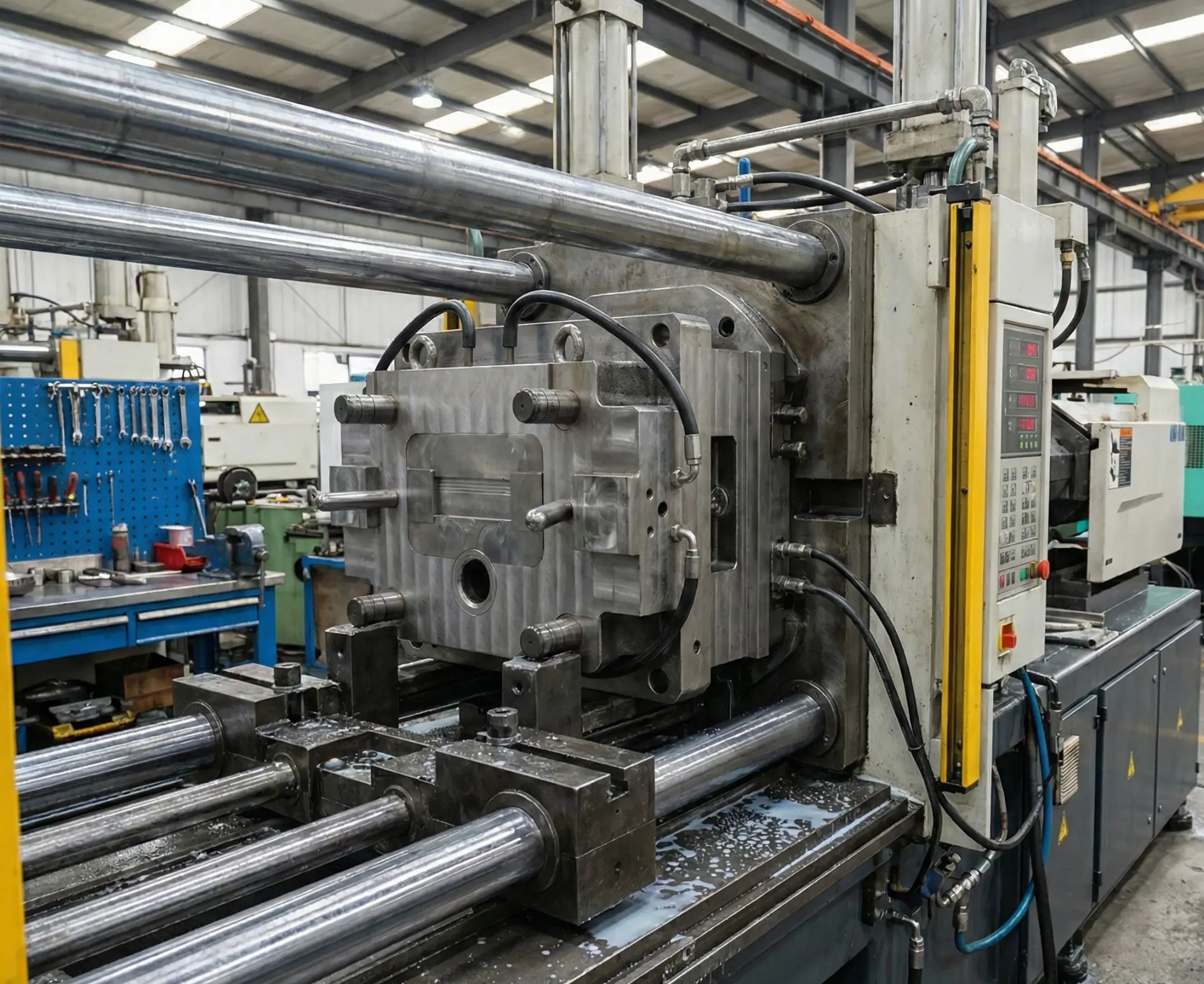

Mass Production

Advanced injection molding equipment ensures quality stability during mass production.

- Automated Production

- Quality Monitoring

- On-time Delivery

- Flexible Capacity

Surface Treatment

Offer painting, plating, texturing and other surface treatment options to enhance product quality.

- Spray Painting

- Electroplating

- Texture Finishing

- Laser Engraving

2K Two-Color Molding

Two-color injection technology, one-time molding of multi-color products, improving design freedom.

- Two-color Molding

- Precision Alignment

- Cost Reduction

- Enhanced Quality

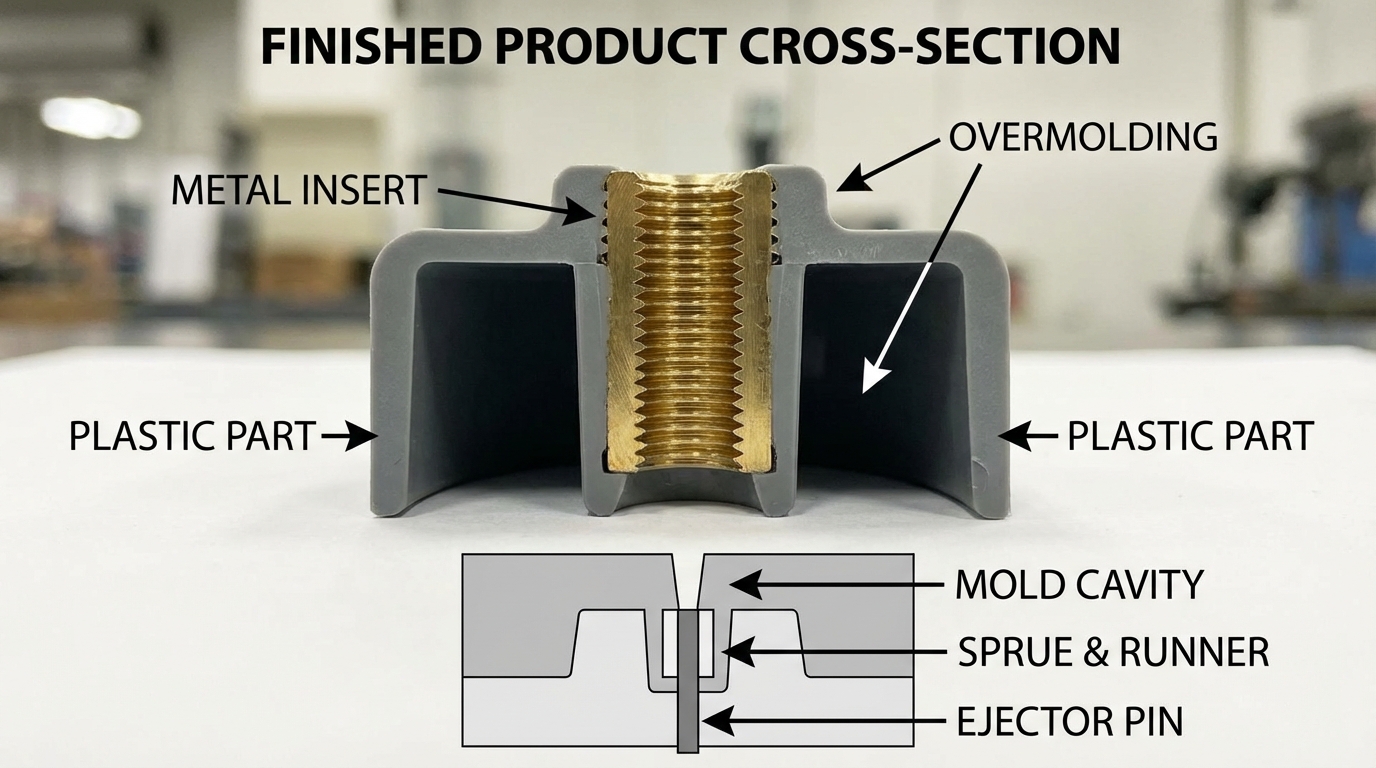

Insert Molding

Integrate metal or other material inserts with plastic in one molding, enhancing product strength.

- Metal Inserts

- Nut Embedding

- Strength Enhancement

- Reduced Assembly

Our Process

Complete Journey fromConcept to Product

We provide one-stop plastic injection molding services, from design consultation to mass production delivery, with excellence in every step.

Design Consultation

Expert guidance on design optimization

3D Printing Samples

Rapid prototyping for design verification

7-14 daysSample Confirmation

Client review and design refinement

Mold Design & Discussion

Detailed mold structure design and analysis

Schedule Confirmation

Detailed production timeline planning

Mold Manufacturing

Precision CNC machining and mold fabrication

Vertical: 20 days / Horizontal: 45+ daysTrial Molding

First trial run to verify mold performance

Final Approval & Production

Client final approval and mass production start

Material Library

ProfessionalMaterial Database

We offer a wide range of plastic material options to meet different product characteristics, from heat resistance to high toughness.

Polycarbonate

High transparency, high strength, and impact-resistant engineering plastic, suitable for applications requiring high strength and transparency.

Acrylonitrile Butadiene Styrene

Excellent processing performance and surface gloss, one of the most commonly used engineering plastics.

PC/ABS Alloy

Combines the strength of PC with the processability of ABS, providing the best comprehensive performance.

Polypropylene

Lightweight, chemically resistant, and highly tough general-purpose plastic with high cost-effectiveness.

Polyvinyl Chloride

Good weather resistance and flame retardancy, widely used in construction and electronics industries.

Liquid Silicone Rubber

Liquid silicone rubber offers excellent flowability and molding precision, ideal for high-precision medical and food-grade products.

Nylon

High strength, wear-resistant, widely used in engineering parts, gears and other mechanical components.

Polyacetal

Excellent dimensional stability and fatigue resistance, suitable for precision gears, bearings, etc.

Thermoplastic Polyurethane

Good elasticity, wear-resistant, commonly used in phone cases, shoe materials and other products requiring elasticity.

Success Cases

Excellent Results in Diverse Industries

We provide high-quality plastic injection molding solutions for various industries, from consumer electronics to medical devices. Each project showcases our technical expertise and quality commitment.

Consumer Electronics

Providing premium enclosures for smartphones, wearables, audio equipment, and other consumer electronics.

Industrial Electronics

Providing durable enclosures for control systems, sensors, power supplies, and other industrial equipment.

Medical Electronics

Providing compliant enclosures for medical devices, diagnostic equipment, patient monitors, and other medical products.

Real Client Stories

Deep Partnerships

How we help clients across industries solve manufacturing challenges

Medical Device Components Partnership

30+ years partnership, from cable supplier to full-service partner

Law Enforcement Supply Chain Integration

30+ years partner, helped relocate production to Vietnam

Sports Tech Startup Support

From 5-person startup to Series A, 8 months to production

Get Quote

Chat with our AI assistant to learn about our services, sign NDA, and upload files for professional evaluation.

Start a conversation with AI